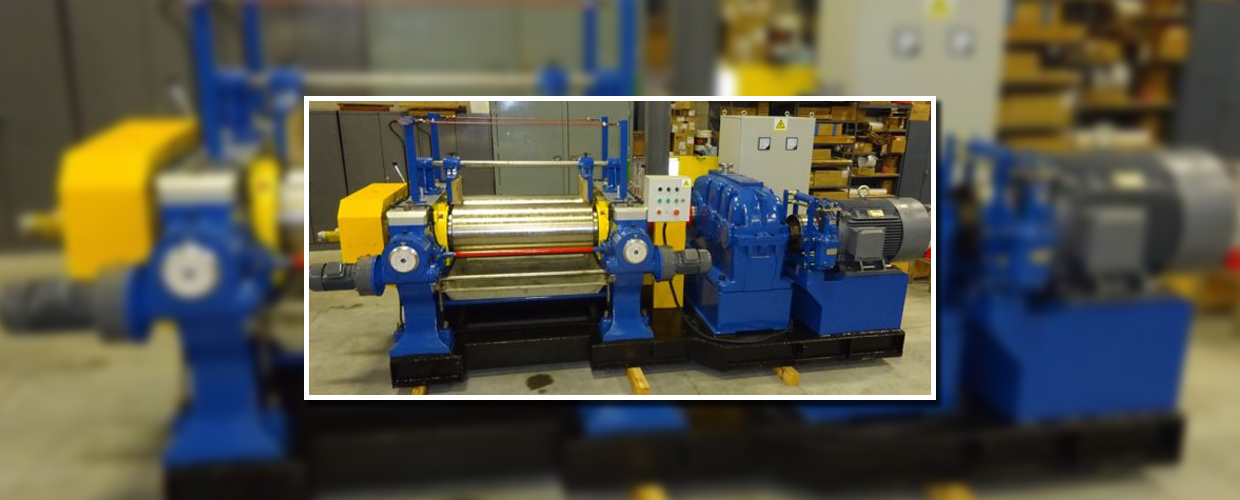

ViamTek Machinery offer a wide range of most advance and high quality Mixing Mills at competitive rates to the clients also known as two roll mill with anti-friction spherical Roller bearings. ViamTek Mixing Mills are sturdy enough to mix newer and tough compounds in a silent, trouble-free, smooth manner and are very durable and reliable in operation. The compounds may be of rubber, plastic/polymer or tile compound. We offer mixing mills with Anti friction spherical roller bearings having built in swivel action. Saves 25 TO 30% Power loss due to BUSH BEARINGS AND BULL GEAR. We specialize in rubber processing machinery, rubber grinder mill and various other rubber machineries that are manufactured in our factory in Mumbai, India.

ViamTek Mixing Mills are used

- As dump mills below the internal mixer for compounding and sheeting out

- Hot & warm up compound and feed mills for calendar and extruders

- For re-mixing

- For plain compounding and mixing

Silent Features & Benefits

Silent Features & Benefits

- Rigid & Reliable Construction to mix newer and tougher compounds

- Main Stand & Bearing Housing Steel Casting

- Base frame single beam construction of welded fabricated for maximum stability

- Chilled cast iron roll with surface hardness

- Uni-drive with main rolls journals with anti- friction roller bearings

- Anti-friction spherical Roller bearings to saves 25 to 30% Power consumption

- Energy efficient STANDARD Make Motor

- Automatic lubrication system for main bearing for smooth operation

- Water cooling system with universal rotary joint 100% Roll cooling

- Nip Gap Adjustment with motorised and Manual Hand wheel for parallel sheeting

- Electrical Control Panel “SIEMENS” System house Reverse & Forward ‘INCH’ facility

- Complete safety feature for operator and Machine

SAFETY FEATURES

- Emergency brakes with limit switch

- Emergency brakes Chest bar with reverse INCH facility provided

- Emergency brakes Provided on both sides to stop machine in ⅓rd Revolution of Front Roll

- Auto reversible control panel

- Hydraulic & Electromagnetic Thruster Brakes

Trouble Free Maintenance

- Precise Heat Transfer with chilled Cast Iron Roll & uniform wall-thickness with large cooling pockets restricts heat build-up in compound during mixing. Cored or Peripherally drilled Rolls are offered

- Single beam fabricated base structure makes mill silent and vibration free

- Manually or Motorized Operated Nip adjustments with numerical controls available

- Quick & Easy Installation Mills with Vibromount no needs of foundation or time consuming installation procedures

| STANDARD RANGE OF MIXING MILL AVAILABLE : | ||

| ROLL SIZE | POWER / RPM | BATCH CAPACITY |

| 6” x 13” | 7.5HP /1000 | 1.5 Kgs |

| 8” x 18” | 10HP /1000 | 2.5-3 Kgs |

| 10″ x 24″ | 15HP /1000 | 6-9 Kgs |

| 12″ x 30″ | 30HP /1000 | 15-20 Kgs |

| 14″ x 36″ | 40HP /1000 | 25-28 Kgs |

| 16″ x 42″ | 60HP /1000 | 35-40 Kgs |

| 18″ x 48″ | 75HP /1000 | 40-50 Kgs |

| 22″ x 60″ | 120HP /1000 | 60-80 Kgs |

| 26″ x 84″ | 200HP /1000 | 90-110 Kgs |

| Friction Ratios : 1:1.05 To 1:1.22 | ||

ViamTek Machinery also offer 16”X 42” to 22”X 60” Mixing Mill

Rubber Mixing Mill Equipped with STOCK BLENDER & HYRAULIC STOCK GUIDE

Rubber Mixing Mill also offer equipped with CORED & PERIPHERALLY DRILLED ROLL